GMTS can thoroughly investigate the quickest, safest, and most economical methods for completing both critical path project scope and discovery work during the execution phase. Utilize comprehensive project controls, quality control, and engineering to significantly impact a project’s bottom line.

Project Controls

With a sharp focus on stakeholder collaboration, meticulous planning, and continuous improvement, GMTS strives to deliver projects that exceed expectations and create lasting value.

- Detailed Planning: Comprehensive project schedules, work breakdown structures (WBS), and resource allocation plans are developed to map the project trajectory.

- Budget Management: Project budgets are established and managed, maintaining close oversight of expenditures and cost control.

- Risk Management: Project Readiness Review system identifies potential risks and develops mitigation strategies, also setting up response plans to minimize issue impacts.

- Performance Monitoring: Project progress is assessed against pre-set schedules and key performance indicators (KPIs), identifying trends and anticipating deviations. Status reports are shared regularly.

- Change Management: Change requests are assessed to ensure alignment with project objectives, evaluating impacts on schedules, budgets, and resource allocations.

- Document Control: A robust system to manage all project-related documentation is maintained.

- Resource Optimization: Resource gaps and bottlenecks are identified, proposing solutions for efficient resource utilization.

- Post-Project Reviews: Post-project reviews are conducted to identify lessons learned and best practices to enhance future project control processes.

GMTS’ project management approach is centered around continuous improvement, ensuring continual enhancement to practices for better project outcomes.

Quality Control

GMTS’ quality system procedures encompass meticulous record maintenance and continuous improvement initiatives and are designed to exceed expectations and ensure compliance with all regulatory, customer and company quality requirements.

QC/Inspection Plan and Package Development: Project-specific quality control/inspection plans and packages are developed per client requirements.

Quality System: Procedures are developed, implemented and continuously enhanced to ensure consistent project execution.

WPS/PQRs & WPQs Development: All necessary welding procedure specifications (WPS), procedure qualification records (PQR), welder performance qualifications (WP) are developed internally.

Periodic Audits: Regular informal audits are performed (both in-shop & field) to ensure project quality and manual compliance.

Policy and Code Interpretation Support: Company personnel are supported in interpreting company policies and code/jurisdictional requirements.

Site Inspection Compliance: Site inspectors adhere to code/jurisdictional requirements and meet all regulatory, customer, and company quality requirements.

Welder Stencil Management: Revocation and re-issuance of Welder Stencils are handled as required.

Training: Training to maintain high-quality standards is provided.

Our emphasis on quality and continuous improvement ensures that we deliver projects that meet the highest standards, keeping your satisfaction at the forefront.

Engineering

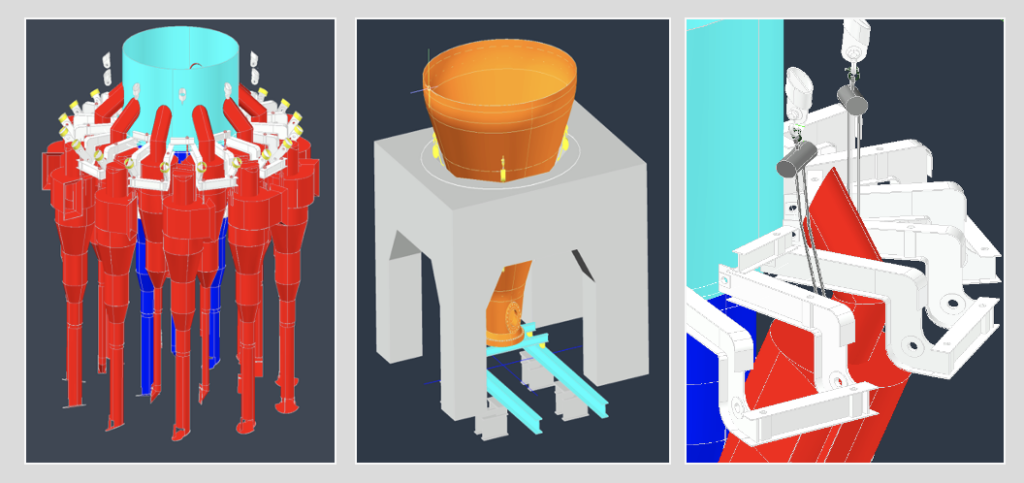

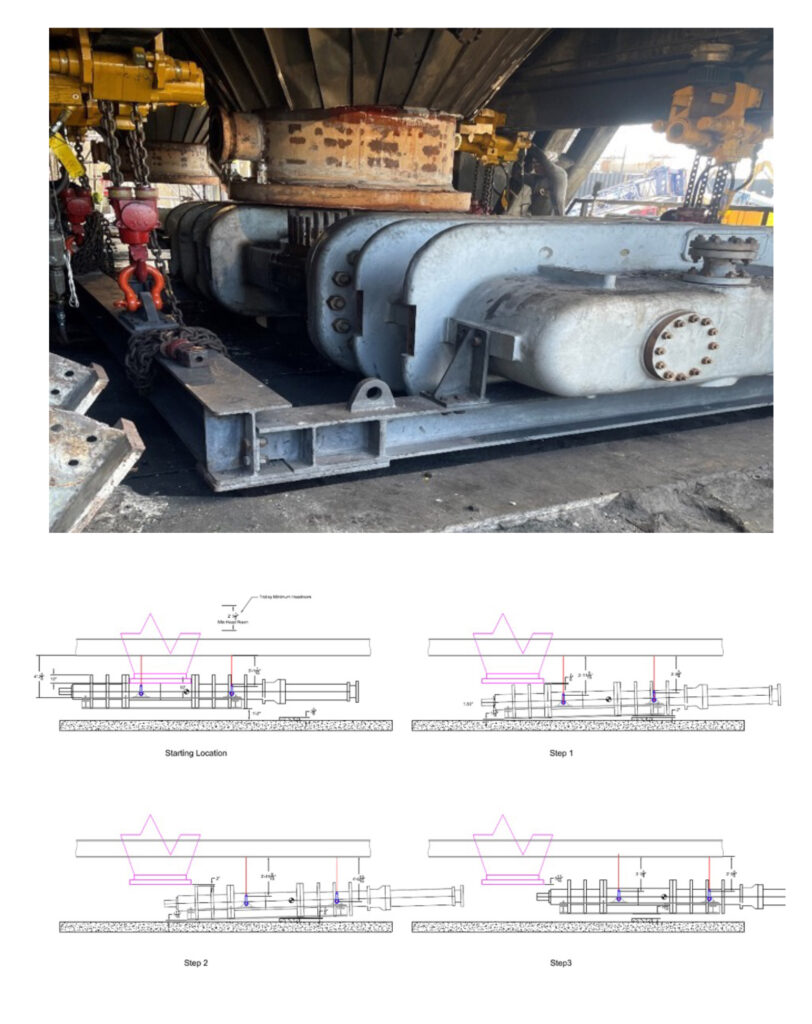

GMTS’ in-house engineering designs heavy-lift operations, and advanced rigging. Project operations’ safety, efficiency, and feasibility are ensured through meticulous planning, expert selection of equipment, and innovative engineering solutions.

Constructability Modeling: Cutting-edge modeling techniques and extensive studies are utilized to evaluate project designs’ practicality and efficiency.

Heavy-Lift Crane Evaluation and Selection: The most suitable heavy-lift cranes are assessed and selected to ensure smooth and safe project execution. Innovative uses of cranes beyond traditional lifting are also explored, such as using cranes for additional support during critical operations.

Heavy-Lifting and Specialty Rigging Planning: Comprehensive plans for all heavy-lifting and rigging operations are designed to focus on safety and efficiency.

Third-Party Engineering Support: Third-party engineering support is available to complement and enhance project success.

GMTS’ engineering services ensure projects are delivered safely, efficiently and successfully, meeting and exceeding expectations.